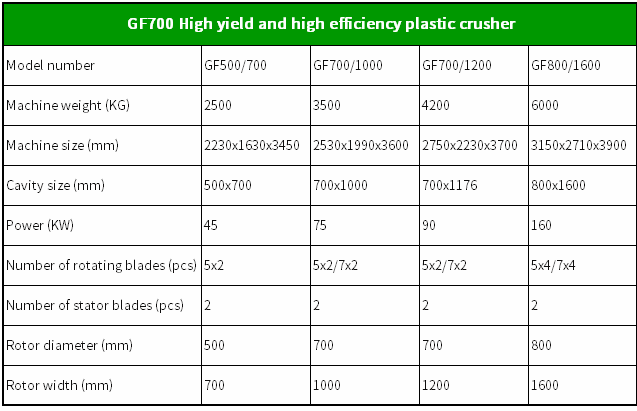

GF series is an efficient, low energy crusher, designed for thin film, hollow vial, PET bottle. According to the characteristics of different materials, the crusher is equipped with a variety of rotor models for choice. Rotor diameters range from 500mm to 800mm. The minimum width of the rotor is 700mm and the maximum is 1600mm. A targeted rotor structure can be designed to achieve the best crushing effect. Special welding process is used for the whole steel structure to meet the demand for unbreakable materials. Large rotor bearings, tool holders and rotors combined with standard V-shaped cutting technology are conducive to improving cutting and recovery efficiency and reducing dust content in recovered materials. GF series crusher has special cutting technology, can recover all kinds of film, small hollow materials, including injection mold parts, bottles, blow mold parts, film and other materials. The crushed flakes are uniform.

relative to the ordinary mill output increased by 20%~40%

comminution out of uniform sheet, conducive to recovery.

effectively reduce the dust content of recycled materials

The details show professionalism

Suitable for a variety of material crushing

Provide professional customization

Demark products