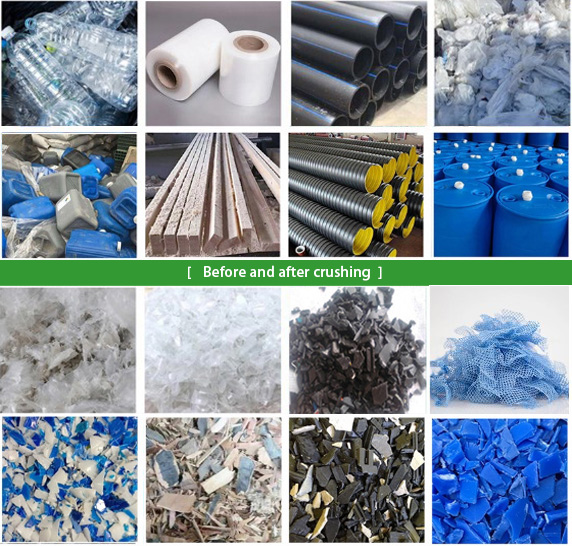

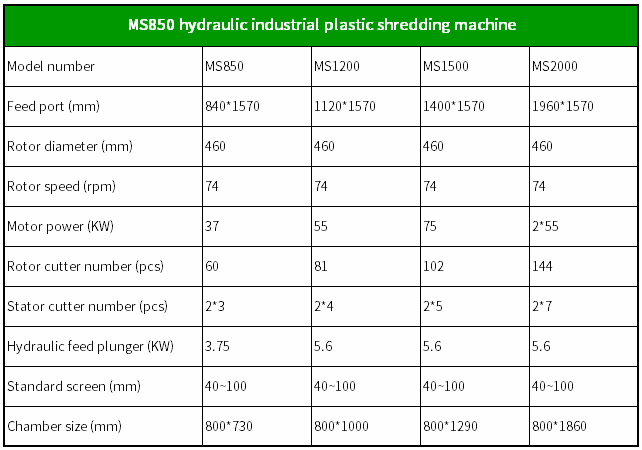

MS series single-shaft shredding machine is specially developed for Demark plastic processing large amount of recycling company models. The series of single shaft shredder is equipped with a powerful adjustable hydraulic push rod. This design can prevent material clogging and reduce the wear of the internal guide rail. Shredding machines feature DEMARK effective V-shaped rotors with a diameter of 450mm, ranging in width from 1000mm to 2000m. Hydraulic workstation and shredding chamber closely combined, not only save space and protect the hydraulic station, easy to replace and maintain. The design of standard V-shaped rotor, supporting tools, tool handles, external bearings, hydraulic screen support, etc., have been recognized by customers and good feedback. MS series shredding machine can be further adjusted according to customer requirements for garbage disposal design. Customers can choose from cooling systems, rotor surface hardening treatment and other anti-wear devices. MS series shredding machine design can meet the requirements of various Demark plastic recycling enterprises, including general Demark recycling, electronic Demark recycling, household Demark recycling treatment. There are many kinds of recyclable materials, such as various plastic blocks, plastic pallets, pipes, films, woven bags, etc., as well as all kinds of electronic wire Demark, ICB drums, large home appliance casings, Demark paper, wood and various organic materials. The size of the screen can be determined according to the crushing material and the next processing requirements.

can prevent material clogging, reduce internal guide wear

save space and protect the hydraulic station, easy to replace and maintain

equipped with a diameter of 450mm V-shaped rotor, width from 1000mm to 2000m

The details show professionalism

Suitable for a variety of material crushing

Provide professional customization

Demark products