In the field of HDPE/PP/LDPE recycling projects, most of the materials come from urban and industrial collection points, which vary in size, and the raw material composition varies from country to country, even if the HDPE-PP-LLDP composition is different in the same country. DEMARK Plastic recycling cleaning line is designed for recycling daily plastic products. By grading, crushing, and washing, clean, reusable materials are obtained for downstream use. This system can process the raw materials are HDPE/PP bottles and utensils, HDPE/PP barrels and boxes, HDPE/PP daily rigid plastics. Hard plastics (HDPE) recovery line capacity of 1,000 kg/h to 4,000 kg/h. Efficient treatment techniques can greatly improve the recovery efficiency.

Solve a variety of waste plastic broken problem

The obvious crushing effect

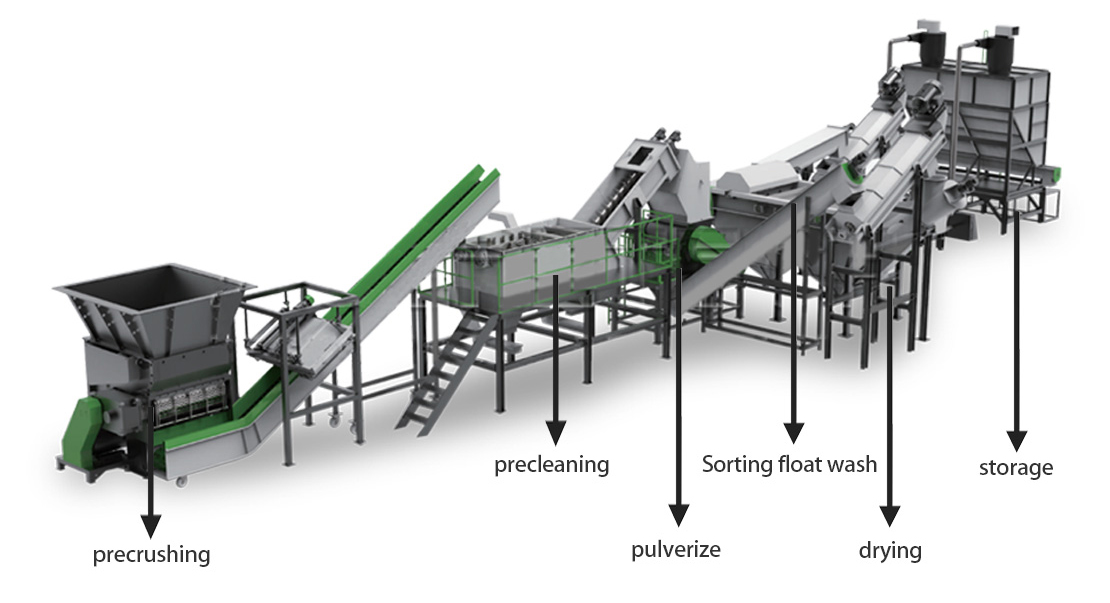

The composition of plastic treatment line

* Used to reduce the size of plastic materials * The hydraulic cylinder space in the cutting room is increased by 35% * Variable faster plunger movement * Less space than traditional horizontal shredders

* Specifically designed to separate heavy contaminants * Separator tank, built-in stainless steel * With pneumatic inlet valve, automatic control of liquid level through electronic inductor * Equipped with a compressor and blower to inject compressed air into the bottom of the tank

* Optimized rotor and crushing chamber design, reduce energy consumption, increase production * The most ideal rotor blade, especially suitable for crushing heavy materials * Precise clearance between rotary tool and fixed tool, rotor design to ensure uniform particles, noise control in the lowest range

*Use cold or warm water for effective cleaning. Improved separation due to about 30%Above * Screen surface separates water and impurities such as paper, organic matter and sand *Easy to replace screen. Rotor with interchangeable paddle *Easy to maintain, easy to assemble and disassemble cover plate

*To further separate and clean the heavy contaminants with gravity > 1g/cm3 from the plastic waste, the material is pushed underwater to separate the final heavy contaminants and discharge the material directly into the screw loader

* Multi-purpose device that can clean residual contaminants from material surfaces and dry plastic sheets at the same time * The sheet is then centrifuged and dried * Dehumidification efficiency: not less than 98% * Washer/dryer shell with stainless steel welded structure

*Intermediate storage of non-mobile materials

Demark products