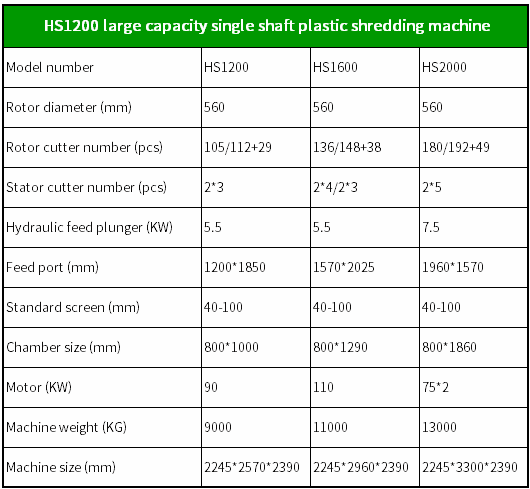

HS series is a large capacity single shaft shredding machine. The redesigned hydraulic pusher not only improves the speed of power transmission and pusher, but also effectively avoids material clogging and internal guide wear. This specially designed device creates about 35 percent of the space in the cutting chamber. This series of shredding machine uses high efficiency V-shaped rotor design. The minimum width of the rotor is 1200mm, the maximum width is 2000mm, and the rotating diameter is 560mm. The rotor is driven by an oversized gear box. Low speed of 85rpm ensures smooth operation of high torque. The hydraulic station is closely combined with the shredding chamber to save space and protect the hydraulic station. It is also easy to replace and maintain. The whole machine is welded by special welding process, which can greatly improve the stability of the whole machine and effectively prevent spatter. At the same time, HS series has all the advantages of other shredding machines, including specially designed rotor knife and tool holder, external bearings, as well as convenient advanced intelligent control system. HS series shredding machine is designed to meet the waste recovery requirements of various industries, including bulk materials, pipes, films, woven bags and all kinds of electronic cable waste, ICB drums, Demark paper, wood and all kinds of organic materials.

improve the power transmission and push speed.

save space, protect the hydraulic station, easy to replace and maintain

can greatly improve the stability of the whole machine, and can effectively prevent spatter

The details show professionalism

Suitable for a variety of material crushing

Provide professional customization

Demark products